QA certification line expansion

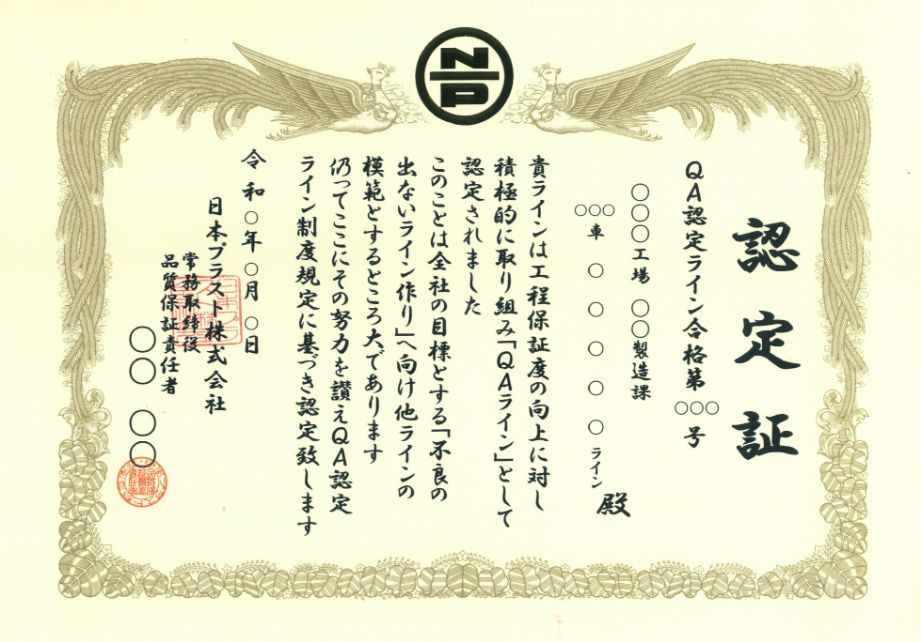

At Nihon Plast, we are expanding implementation of our QA (Quality Assurance) certification line, which evaluates and suggests improvements based on our own evaluation standards system, in order to improve the quality assurance level at each stage of receiving a product from the previous step in the process, manufacturing it as part of the process, and sending it on to the next step in the process. Corporate commendations are awarded to lines that have passed certification and additional commendations are awarded for the first, second, and third year of maintaining certification standards, all of which generates increased motivation within acquisition and maintenance operations.