- TOP

- Technology

- Development Technology

Development

Technology

Nihon Plast’s development technology proactively collects feedback from customers to create new products by implementing a development process that enables us to provide products that exceed customer expectations for safety and comfort. In response to the increasing adoption of electrification and automation and the growing need for improved cabin comfort, Nihon Plast’s proprietary technologies quantify sensory elements such as sight, sound, smell, and touch, and we are using all the technologies we possess to realize them.

Pursuit of possibilities

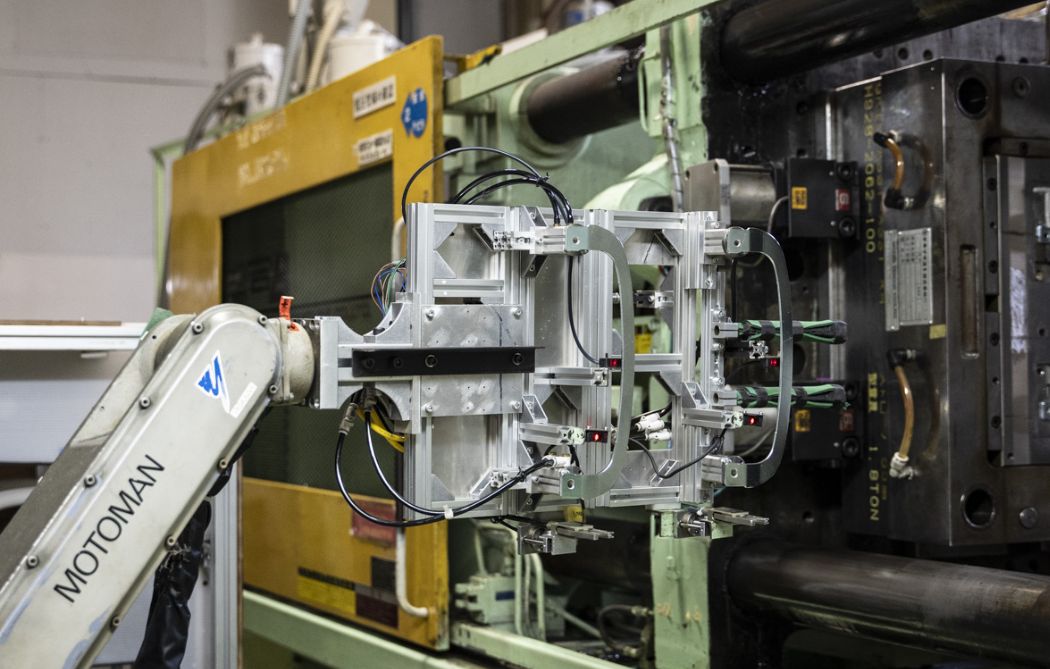

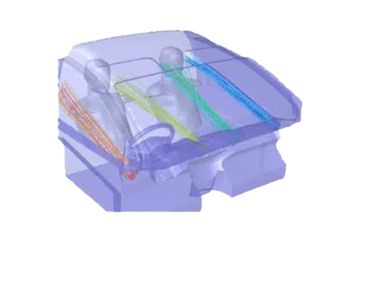

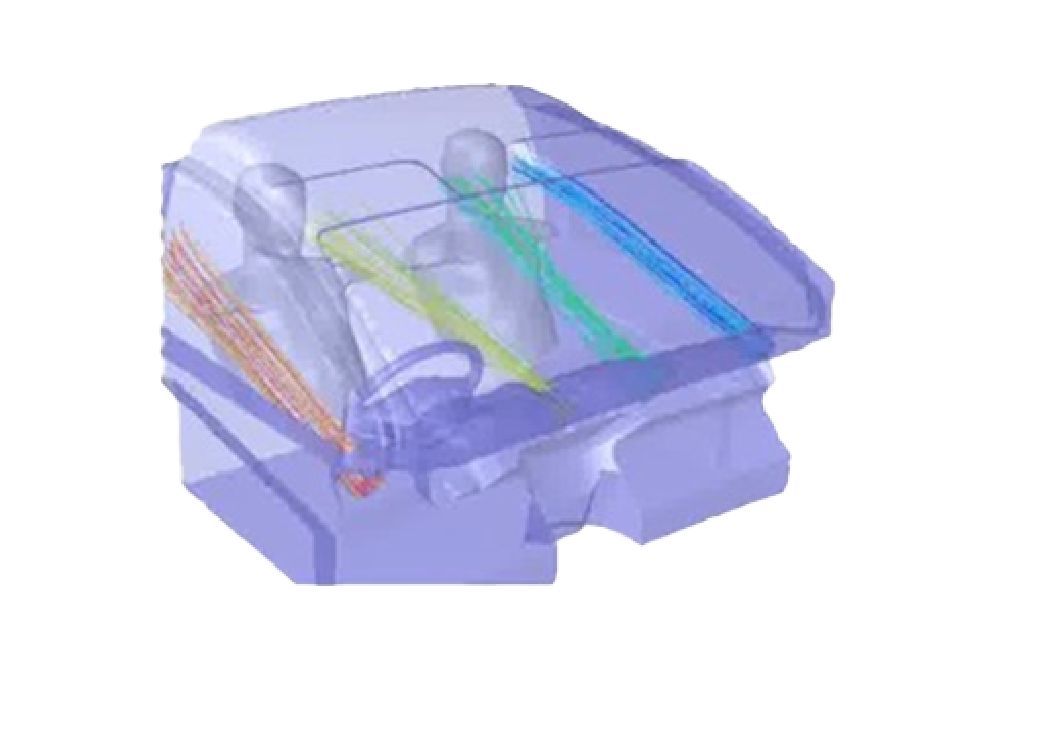

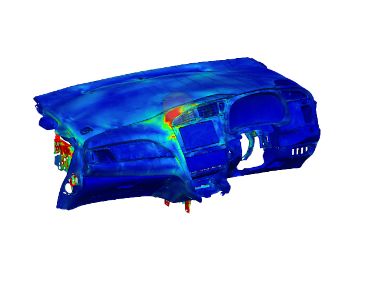

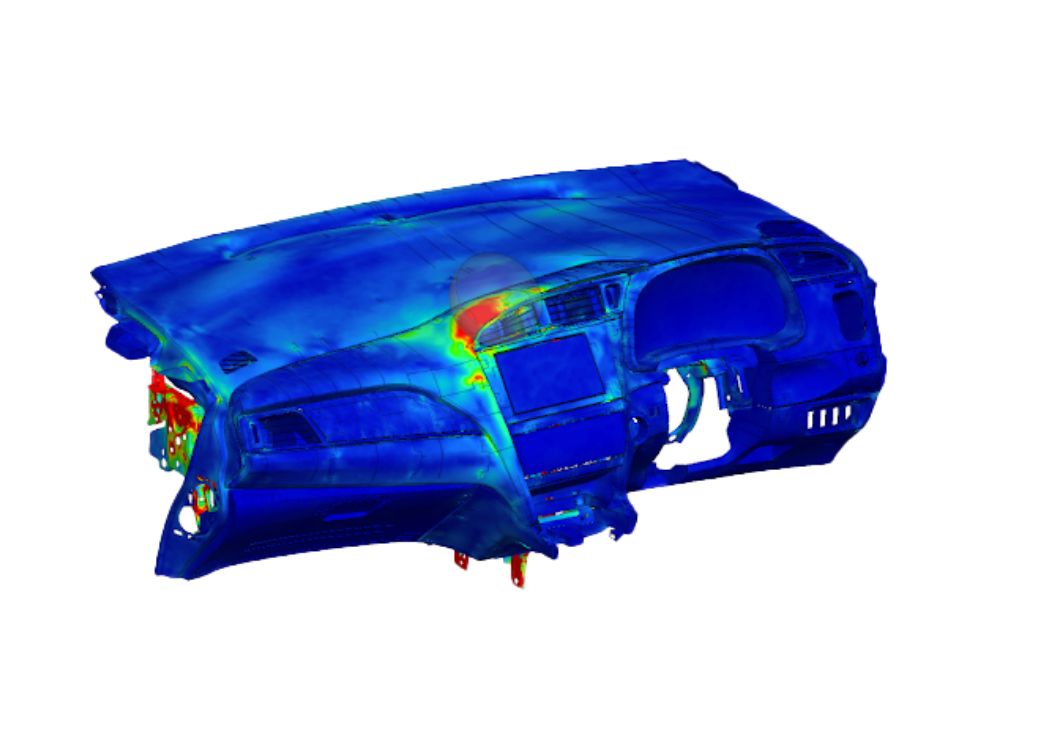

based on CAD & CAE

With all our design data in one central location, we work to improve product design, performance forecasting, and reliability and to shorten development time by building our own production equipment.

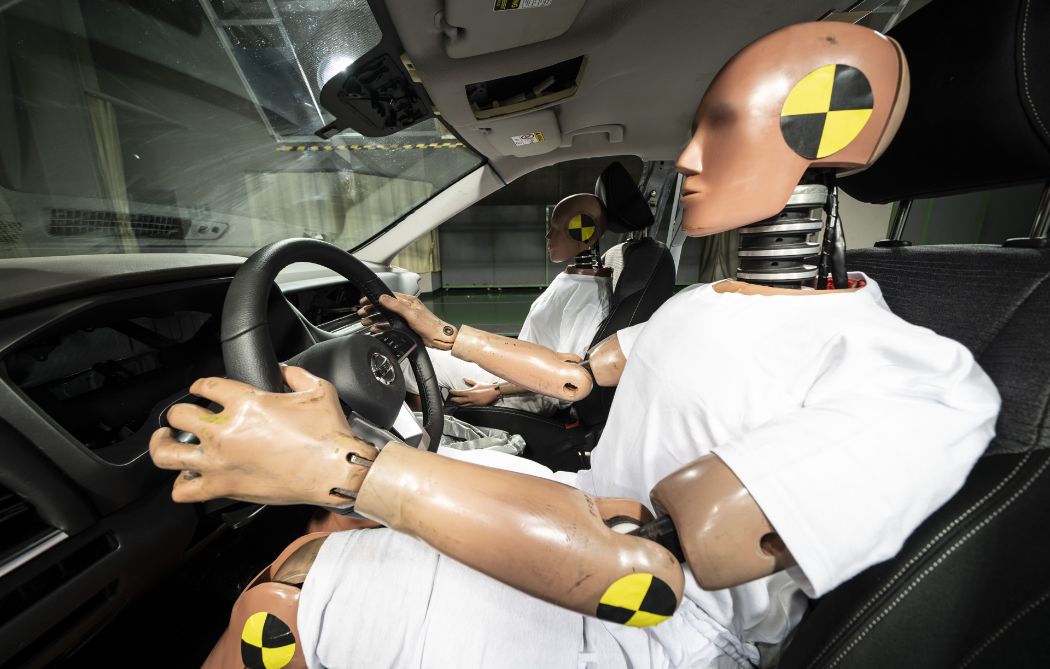

Advanced quality assurance & testing system

Automobiles must maintain sufficient performance even under severe conditions, including weather, vibration, and impact. Nihon Plast ensures the durability of its products with equipment that can reproduce all types of environmental conditions. We develop safety performance with help from a crash-test system. Together with our evaluation techniques unique to individual products, this gives peace of mind to drivers as well as passengers.